Alaska Airlines Flight 261: A Fatal Descent Unraveling Safety Failures and Operational Tragedy

Alaska Airlines Flight 261: A Fatal Descent Unraveling Safety Failures and Operational Tragedy

In the early hours of February 20, 2009, a routine transpacific flight from Los Angeles to Anchorage ended in catastrophe, claiming 88 lives when Alaska Airlines Flight 261 crashed off the California coast. What unfolded was not merely a mechanical failure, but the culmination of systemic lapses in maintenance, supervision, and regulatory oversight—factors that transformed a modest technical issue into a national aviation tragedy. The investigation revealed how overlooked warnings, supply chain mismanagement, and inadequate training converged to seal the fate of Flight 261.

The Flight and Its Final Moments

Alaska Airlines Flight 261, a Boeing 737-200 carrying 156 passengers and crew, departed LAX at 7:07 p.m. PST en route to Anchorage. Seventeen minutes into the journey, mid-flight, habitants felt severe exterior vibrations.Pilot reports indicated “severe, violent shaking” beginning at 7:24 p.m., with a loud metallic “clanging” sound just minutes prior—an auditory warning lost amid routine operations. The aircraft, descending from cruising altitude, began a rapid descent at over 3,000 feet per minute, impossible for a 737 without catastrophic failure. At 7:26 p.m., rescue authorities lost signal, and the wreckage was found more than ten miles off the San trickle coast near Point Vicente.

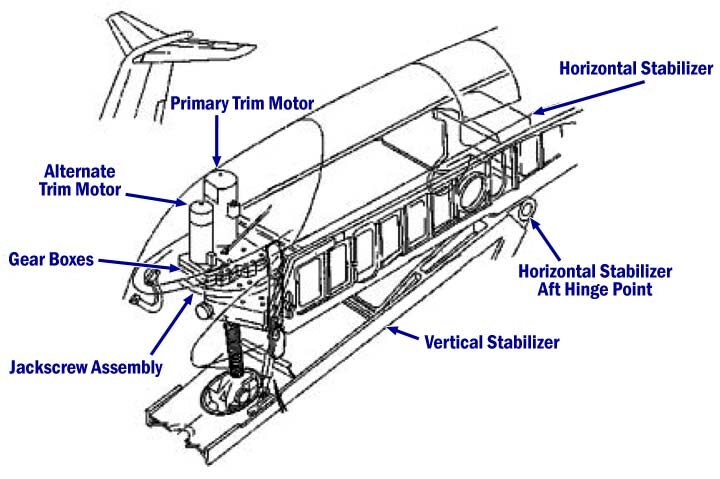

Technical Roots: The Faulty Flight Control Actuator

The National Transportation Safety Board (NTSB) identified the primary cause: a hydraulic actuator failure that severed control surfaces, disabling the aircraft’s ability to maintain level flight. The actuator, critical for adjusting the horizontal stabilizer and other flight surfaces, had long exhibited signs of wear. Despite known issues, the Component Repair Organization (CRO) assigned to Northrop Grumman’s maintenance division failed to replace the worn parts despite documented problems dating back to 2006.- Subsystem failure: The left hydraulics actuator controlled flight stability. - Fragmented oversight: Maintenance logs showed recurring warnings, but no corrective action. - Supplier accountability: The CRO lacked certification for key aircraft systems repairs.

As soon as 2007, mechanics reported erratic behavior, yet replacement timelines were delayed. The actuator’s deterioration proceeded unchecked, culminating in the fatal severance during Flight 261’s descent.

Human and Organizational Contributors

Human error and organizational culture played deeper roles.Crew automated checks lacked assurance—pilots were not trained to verify actuator function meaningfully, relying on systems that failed invisibly. Airlines and operators prioritized schedule over safety margins, normalizing postponed maintenance. The FAA’s oversight was reactive rather than proactive, permitting known defects to persist.

A sobering detail: Northrop Grumman’s repair division had only limited authority over Boeing 737 airframes. Meanwhile, dispatchers downplayed critical alarms as “non-urgent,” a pattern mirrored across maintenance networks. Lessons Not Fully Learned—A Legacy of Caution In the wake of the crash, the aviation industry tightened oversight on fleet maintenance, mandating stricter CRO accreditation and real-time diagnostic protocols.

Alaska Airlines revised its technical protocols, emphasizing redundancy checks. Yet, the Flight 261 tragedy endures—a stark reminder that systemic vigilance—not isolated fixes—guards against disaster. As one recovered pilot’s memoir reflects: “We flew with what we knew, but not what was real.” In the silence of the crash site, history remembers: readiness is not assumed, it is earned.

Related Post

Is Chris Stapleton a Democrat? Exploring the Political Views of Country’s Rising Star

ExampleOfNotAFunction: The Hidden Friction in Building Smarter Systems

Dragon Ball Super: Granola Saga – A Complete Recap of the Shogun’s Power Surge

Bridging Waste and Wealth: How Wastewater Treatment Painlessly Transforms Trash into Treasure