Disk Rotational Inertia: The Hidden Force Shaping Data Reliability

Disk Rotational Inertia: The Hidden Force Shaping Data Reliability

At first glance, rotational inertia in hard disk drives may seem like a niche physics concept irrelevant to everyday computing—but beneath the sleek casing of modern SSDs and HDDs lies a principle that quietly governs performance, stability, and longevity: rotational inertia. Defined by a system’s resistance to changes in rotational speed, disk rotational inertia fundamentally impacts how drives respond to data commands, power fluctuations, and mechanical stress. Understanding this concept is not just academic—it’s essential for engineers, manufacturers, and anyone invested in building durable, efficient storage systems.

Far from a mere theoretical curiosity, rotational inertia shapes everything from read/write speed consistency to thermal behavior and even failure prevention in high-load environments.

What Is Rotational Inertia in Disk Drives?

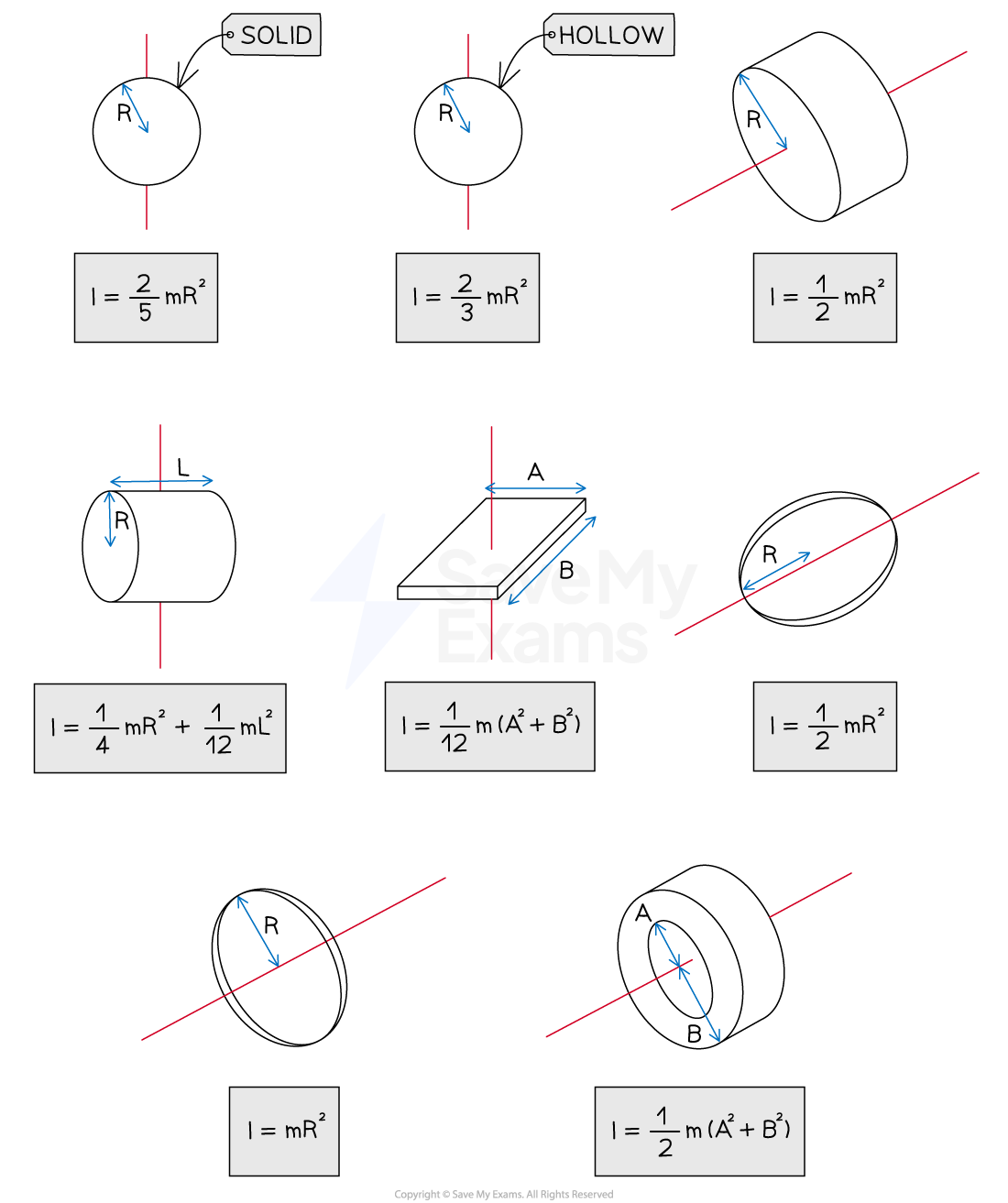

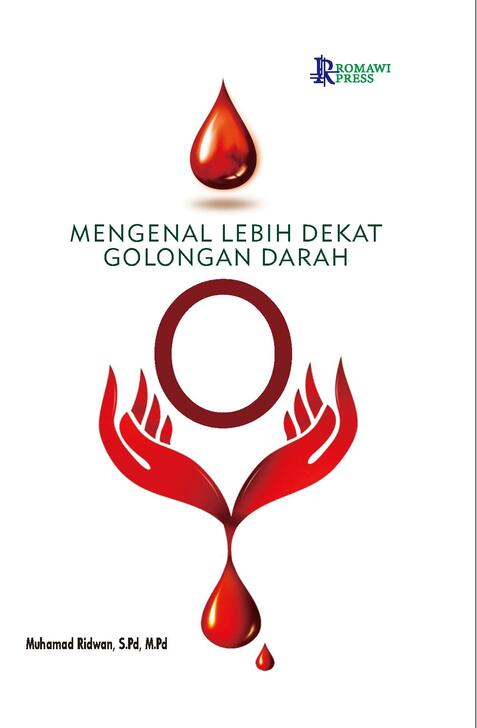

Rotational inertia, or moment of inertia, quantifies an object’s resistance to acceleration or deceleration around a rotational axis. For a hard disk, this means how much energy is required to start or stop the disk spinning—typically measured in kilogram-meters squared (kg·m²) for physical disks and adapted for solid-state components.In traditional hard disk drives (HDDs), rotating platters spin at speeds exceeding 5,000 RPM, storing terabytes of data in ultra-fine magnetic precision. The inertia of these massive rotating masses influences system dynamics in subtle yet critical ways. Each disk platter—often a glass-reinforced composite—possesses a significant rotational inertia that determines how abruptly it accelerates or decelerates.

A higher inertia means the platter resists sudden changes in rotational speed, creating a natural buffer against abrupt power shifts. This property is vital when a drive transitions between idle and active states or recovers from unexpected load spikes. Engineered correctly, optimal rotational inertia contributes to smoother, more stable data access and minimizes mechanical wear over millions of read/write cycles.

Engineers design drives to balance high rotational inertia with responsiveness: too much inertia slows startup and read/write initiation, while too little introduces instability and mechanical fatigue. Modern HDDs and hybrid drives leverage precision balancing of rotor mass distribution, magnetic rotor geometry, and optimized bearing systems to achieve a responsive yet stable rotational profile. This delicate equilibrium ensures that data transfer remains consistent and reliable, even under fluctuating system demands.

Rotational inertia also interacts closely with thermal dynamics. As platters spin, friction and electromagnetic forces generate heat; changes in rotational motion alter heat dissipation patterns. Slowing or accelerating a disk abruptly can cause localized temperature gradients, potentially affecting magnetic media stability and longevity.

Drives engineered with proper rotational inertia distribute thermal stress more evenly, reducing hot spots and prolonging component life.

Real-World Implications: Performance, Durability, and Controversy

Consider the performance of enterprise-grade storage arrays. In data centers demanding millisecond-level latency and atomic-level precision, rotational inertia directly affects time-to-first-byte and consistent data access performance. Low-inertia drives enable rapid recovery from command bursts but risk subjecting sensitive read/write heads to inconsistent gyroscopic forces.Conversely, drives optimized for maximum inertia stabilize motion at the expense of quicker latency—trade-offs engineers navigate based on workload profiles. The debate intensifies in portable devices: smartphones and laptops prioritize speed and responsiveness. Here, drives with lower rotational inertia enable faster startup and snappier app launches, albeit at the cost of short-term durability under sudden load changes.

Manufacturers counter this by incorporating buffer memory and dynamic power management, effectively “simulating” low-inertia behavior without sacrificing structural stability. “Rotational inertia is the silent conductor of mechanical harmony inside a disk,” says Dr. Elena Rostova, leads physicist at Quantum Storage Dynamics.

“It’s not the flashiest spec, but it’s foundational—either data flows efficiently, or the system bets on brittle performance with unknown long-term cost.” This sentiment reflects industry consensus: rotational inertia isn’t merely a hurdle to overcome but a lever to tune for optimal function. In reliability assessments, rotational inertia influences Mean Time Between Failures (MTBF). Platters subjected to frequent, extreme speed changes—due to poor inertia design—accelerate bearing wear and magnetic media fatigue.

Manufacturers now use finite element analysis and laboratory stress testing to fine-tune disk geometry, minimizing inertial shocks that degrade performance over time. In high-reliability applications such as aerospace, undersea servers, and financial data centers, inertia engineering is non-negotiable.

Modern hard disks exemplify the challenge: engineers shape composite rotor materials—carbon fiber laminates in premium models—to deliver high inertia in compact form factors.

These materials allow rotational masses exceeding 200 kg·m² per platter while maintaining low rotational impedance. The result? Systems that stabilize magnetic alignment, reduce vibration, and sustain long-term operational integrity even amid demanding workloads.

This precision increases both lifespan and data integrity—transforming a physical property into a performance multiplier.

The Future of Rotational Inertia in Driving Technology

As data demands surge toward exascale computing and edge AI, rotational inertia remains a critical variable in next-generation storage design. While solid-state drives sidestep mechanical limitations, hybrid and adaptive storage solutions increasingly integrate mechanical drives with intelligent inertia management. Emerging technologies like micro-electromechanical systems (MEMS) and flywheel-based buffering may redefine how rotational inertia is applied—for instance, using precisely controlled spinning masses not just to store data, but to stabilize power and timing flows across heterogeneous systems.Automotive and industrial IoT applications are already exploring smart inertial compensation, where real-time monitoring adjusts rotational dynamics to preempt thermal or mechanical stress. These innovations suggest rotational inertia will evolve from a passive physical trait into an active,

Related Post

Unlock Grand Theft Auto: Vice City Sites PPSSPP – More Life Than Ever on Your PS4 Emulator

Unlock Walker County Jail Records: How to Trace Local Inmates Through the Walker County Inmate Search

Mengenal Lebih Dekat: Negara Nikaragua – Where Central America’s Soul Unfolds

San Diego to Rosarito: How California’s Coastal Rivals Connect & Compete Across Borders