Mastering 11 In Cm: The Hidden Standard Shaping Precision Engineering

Mastering 11 In Cm: The Hidden Standard Shaping Precision Engineering

In an era where accuracy defines success across industries, the 11 in cm standard—officially recognized in metrology and manufacturing—acts as a quiet but powerful benchmark for precision. Measuring just 11 centimeters, this unit transcends its physical dimensions to represent a globally adopted reference for calibration, measurement, and quality control. From automotive tolerances to aerospace components, engineers rely on this scale to ensure consistency that underpins safety and performance.

Understanding 11 in cm is not just about numbers—it’s about mastering a universal language of accuracy that engineers and technicians use daily.

The Origins and Global Acceptance of 11 In Cm

The emergence of 11 in cm as a formalized standard traces back to international efforts in industrial metrology during the late 20th century. As global supply chains expanded, the need for a single, unambiguous measurement unit became urgent to minimize errors between manufacturers, suppliers, and regulators.First adopted by the International Organization for Standardization (ISO) in calibration protocols, 11 cm established itself as a critical benchmark—particularly in Europe—where it supports precision tasks in mechanical engineering, electronics assembly, and instrument manufacturing. Unlike regional units such as inches or fractions, 11 in cm provides clarity in cross-border projects, reducing ambiguity and enabling faster, more reliable production cycles.

Raising adoption, this standard now features prominently in ISO 8501 surface standards and European machining specifications, serving as a cornerstone for quality assurance systems.

Its adoption reflects a broader shift toward global consistency in engineering practices.

Practical Applications of 11 In Cm Across Key Industries

The utility of 11 in cm is most evident in fields where micrometer-level precision shapes outcomes. In automotive manufacturing, critical components—such as engine valve clearances, brake rotor thicknesses, and transmission housing tolerances—routinely fall within 0.1 mm tolerances, with 11 cm serving as a host reference.Aerospace engineers depend on this unit for turbine blade balance testing, sensor alignment, and composite material sampling, where deviations of even 0.2 cm can compromise flight safety. Meanwhile, medical device fabrication uses 11 in cm as a calibration anchor for surgical instrument edges, implant surface finishes, and diagnostic equipment housing, ensuring both functionality and regulatory compliance. Electronics manufacturers employ it for PCB trace thickness verification and micro-connector alignment, where signal integrity demands strict dimensional control.

Across sectors, 11 in cm acts not as a limit but as a calibration anchor—ensuring that components meet exact specifications regardless of origin or scale.

Common Challenges and Best Practices When Using 11 In Cm

Despite its consistency, applying 11 in cm correctly requires attention to common pitfalls. One frequent issue arises from outdated measurement tools—calipers or térmometers calibrated to imperial systems may misinterpret 11 in cm due to internal unit conversion errors.Additionally, translation discrepancies between regional standards can lead to confusion when collaborating across global teams. To mitigate these risks, professionals recommend: - Verifying tool calibration using certified 11 in cm reference blocks - Adopting digital measurement systems with built-in ISO 8501 compatibility - Implementing standardized documentation practices that specify unit context and tolerance bands - Conducting regular training to reinforce precision measurement culture Engineers who treat 11 in cm not as an abstract number but as a traceable, auditable standard significantly reduce errors and accelerate production efficiency.

Industry leaders emphasize that mastery of 11 in cm goes beyond equipment—it demands procedural discipline, continuous training, and systems that embed precision into every workflow.

The Future of 11 In Cm in a Smart Manufacturing World

As automation and Industry 4.0 technologies advance, the role of 11 in cm is evolving—but its foundational importance remains unchanged. Smart sensors, AI-driven quality control, and real-time monitoring systems increasingly integrate with 11 cm reference points to enable predictive maintenance and adaptive manufacturing. Robotic arms calibrated to 11 in cm standards perform micro-assembly with sub-millimeter accuracy, while machine learning algorithms cross-check deviations against calibrated benchmarks to flag anomalies before defects occur.Even as digital twins and IoT ecosystems grow more complex, 11 in cm persists as a grounded, universally understood metric—ensuring that while technology transforms precision, this chapter in measurement remains fixed.

In this new era, 11 in cm is not an outdated relic but a living standard—bridging human expertise and algorithmic intelligence to uphold quality across every production line, every component, and every mission-critical system.

From factory floors to research labs, 11 in cm stands as a silent guardian of precision, proving that in the world of exacting engineering, even the simplest units hold monumental power.

Related Post

Best Hairstyles for Short Hair: Find Your Perfect Look with Confidence

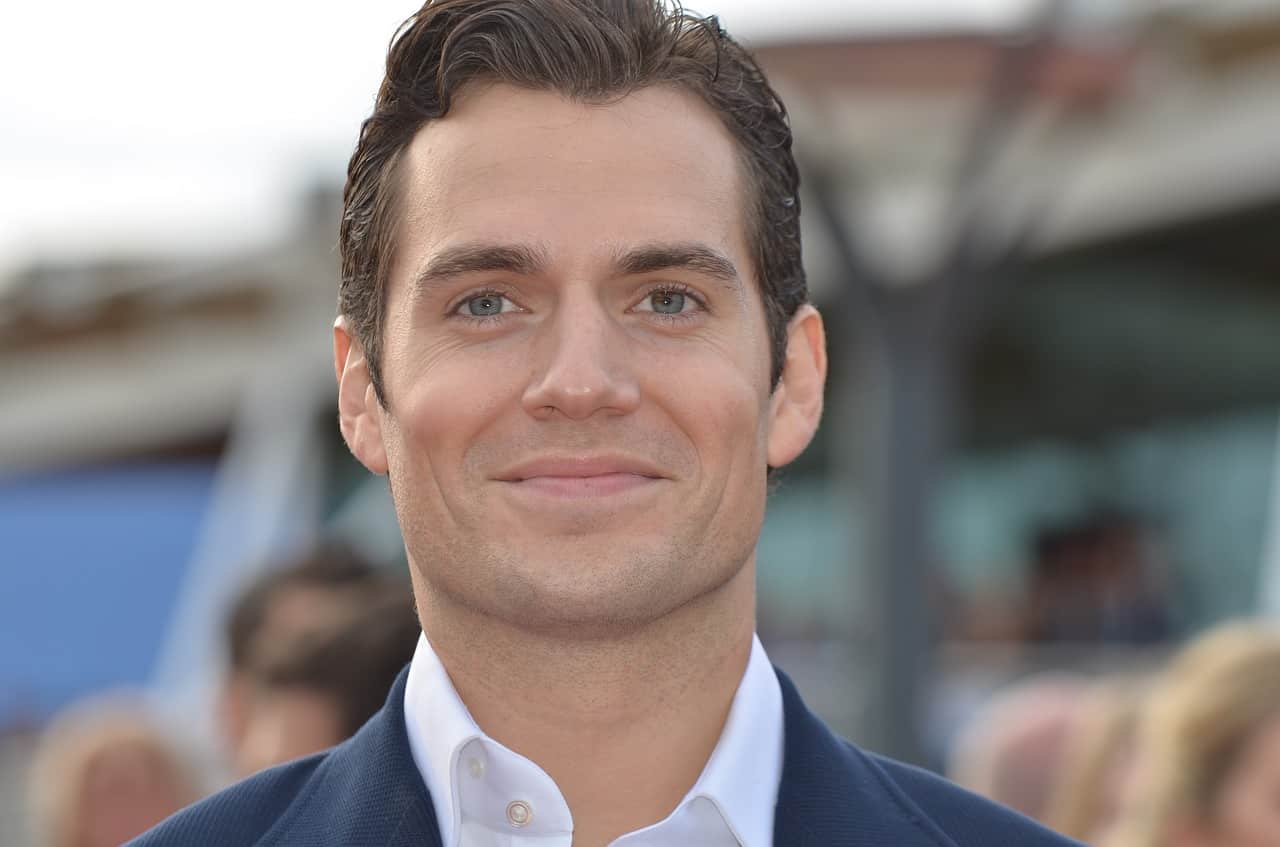

Discover Henry Cavill’s Height: The Science Behind the Iconic Superman Actor

What Does M.I.A. Mean? Unpacking the Evolving Identity Behind the Global Icon

FDIC’s Troubled Banks List Unveiled: What Investors and Citizens Need to Understand