Mastering Industrial Control: How KP, TN, TV, And PID Shape Precision and Performance

Mastering Industrial Control: How KP, TN, TV, And PID Shape Precision and Performance

In modern industrial environments, level, pressure, and flow control are foundational to operational safety, efficiency, and product quality. Yet achieving seamless regulation demands more than intuition—it requires a clear understanding of core analytical and control metrics: KP, TN, TV, and the advanced PID algorithm. These components lock together to enable accurate monitoring, responsive decision-making, and dynamic stabilization in complex systems.

This comprehensive guide unpacks each term, explores their interdependencies, and illustrates how they form the backbone of modern process control.

At the heart of any reliable control system lie four critical parameters: KP (Principal, or process gain), TN (Time Constant), TV (Tuning Victory, often linked to optimal PID parameters), and PID (Proportional-Integral-Derivative control). Together, they provide the framework for measuring system response, predicting instability, and fine-tuning performance.

As control engineer Lawrence Titley once noted, “Control is not just about reacting—it’s about anticipating.” That foresight begins with mastering these key concepts.

KP: The Sensitivity of Process Response

KP, or process gain, quantifies how responsive a system is to input changes—essentially, the amplification factor between a control signal and the resulting process change. Measured in units per percentage change (e.g., % signal → % response), KP reveals the intrinsic sensitivity of a system. A high KP means small adjustments trigger large responses, raising the risk of overshoot and instability; low KP indicates sluggish behavior, increasing delay and reactive lag. - KP is central to early system diagnosis.- Exceeding optimal KP values often leads to oscillations or runaway behavior. - Managing KP requires careful selection of actuator strength and sensor resolution. - As industrial processes demand tighter tolerances, maintaining an ideal KP remains a continuous challenge.

“Understanding your KP is like knowing a car’s throttle sensitivity—push too fast, and stability collapses,” says Dr. Elena Marquez, chief technical officer at Precision Dynamics Inc. “A precise KP allows for fine-tuned adjustments without sacrificing safety.” ---

TN: The Speed of System Reaction

TN, or Time Constant, defines how quickly a system responds to a sustained change.It represents the time needed for a process variable to reach approximately 63.2% of its final value after a step input. A minimal TN enables rapid correction, critical in time-sensitive operations such as pressure relief or level regulation in storage tanks. Conversely, a large TN increases lag, but may reduce susceptibility to noise and overreaction.

The time constant is a fundamental dynamic signature—complementing KP by revealing how fast or slow a process naturally evolves.

Together, TN and KP determine a system’s dynamic class: fast (low TN, low KP), moderate, or slow (high TN, high KP). Engineers use TN not only to predict delay but to tailor control strategies that match system physics.

Real-World Context: In a chemical reactor, a short TN helps avoid pressure spikes during feed changes—yet too fast TN risks amplifying disturbances. Matching TN to KP creates balanced responsiveness.

---TV: Volume, Timing, and the Efficiency of Flow Control

TV, often interpreted as “Time Volume” or “Throughput-Volume balance,” focuses on the relationship between process volume changes and control actions over time.It connects volume flow rates with stabilization delays, helping to estimate how long adjustments linger before a system stabilizes. Though less formally defined than KP and TN, TV captures critical operational dynamics in piping systems and fluid handling.

- In level control, TV governs hold-up and ramp-up duration for pumps or valves. - It influences how quickly a vessel reaches steady state after level changes.- When paired with KP and TN, TV enables accurate prediction of transient behavior. - Neglecting TV can result in under- or over-dosing, contamination, or overpressure. Control specialists emphasize that TV is not a standalone metric but an integrated variable—especially vital in batch processing or continuous production lines where timing mismatches degrade yield and quality.

---

PID: The Adaptive Intelligence Behind Stable Control

PID control remains the cornerstone of modern industrial automation, combining three powerful mechanisms: Proportional (P), Integral (I), and Derivative (D) actions. Each addresses different facets of control challenges. P provides immediate response to deviation, I eliminates long-term error, and D anticipates future trends by reacting to rate of change.When tuned appropriately, PID transforms erratic fluctuations into stable, predictable output.

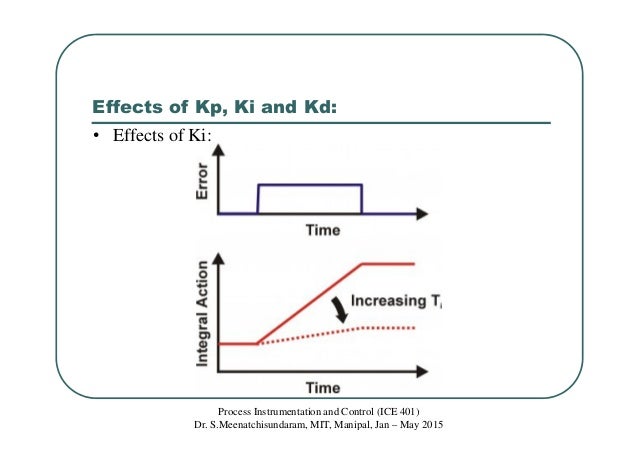

PID’s effectiveness depends heavily on accurate tuning of its three parameters—parameters often governed by TV, TN, and KP data:

- **Proportional (P) Action** directly scales control effort with current error—fast but prone to steady-state offset.

- **Integral (I) Action** accumulates past error, correcting residual bias but risking overshoot if misapplied.

- **Derivative (D) Action** dampens oscillations by responding to error rate—skewed by noise, so filtering is essential.

Mastery of PID requires balancing these elements to suit the system’s KP and TN profile. A system with low KP and rapid TN may demand strong D action to dampen overshoot, while a slow system might need careful P integration to avoid sluggishness. Advanced tuning techniques, such as Ziegler-Nichols or model-based optimization, leverage TV dynamics to refine PID response without trial and error.

---Interdependence: How KP, TN, TV, and PID Work as a Triad

These components rarely operate in isolation.A practical illustration: in a level control loop for a tank, KP defines how sensitive the level is to valve input; TN determines how quickly the level responds; TV shapes the dwell time before the controller adjusts; and PID combines all three into adaptive action. When KP spikes due to nonlinear tubing, KT thrives at low TN, and poorly tuned P can amplify instability—until the PID controller incorporates feedback from TV to adjust gain schedules dynamically.

Engineers emphasize that modern control systems increasingly use adaptive PID algorithms, feeding real-time data from KP, TN, and volume trends to auto-correct gains. This closed-loop tuning allows systems to maintain optimal performance across varying loads, temperatures, and flow conditions—no manual recalibration required.---

Real-World Application: Powering Manufacturing, Chemical, and Energy Sectors

From semiconductor fabrication, where micron-level precision prevents defective wafers, to oil and gas refineries managing multi-thousand gallon tanks, KP, TN, TV, and PID form the invisible skeleton of control. In energy systems, pulsed combustion must stay within tight pressure thresholds—regulated by PID tuned via real-time TN and KP data to prevent flaring and ensure efficiency. The automotive industry leverages these principles to stabilize paint booth spray patterns, while food processing plants rely on level control to avoid product waste and contamination.In each case, a deep grasp of these metrics ensures consistent quality and regulatory compliance. ---

Best Practices for Optimizing KP, TN, TV, And PID Performance

- Regular monitoring of KP and TN prevents performance drift due to wear or environmental shifts. - Use data-driven tuning methods—avoid guesswork.- Integrate TV insights to size control valves, protect equipment, and avoid cycling fatigue. - Deploy adaptive PID frameworks in dynamic environments to sustain optimal response. - Cross-train operators to interpret KP/TN/TV signals, not just mechanical gauges.

“Optimization isn’t a one-time task—it’s a continuous loop of measurement, analysis, and adjustment,” advises control specialist James Lin. “When KP is high, TN fast, TV well accounted for, and PID perfectly tuned, you unlock resilience and efficiency in any process.” ---

In sum, KP, TN, TV, and PID represent more than isolated metrics—they are the language of control engineering. Understanding their interplay transforms reactive operations into proactive precision, enabling industries to operate safely, reliably, and profitably in an era defined by automation and real-time data.

Harnessing these tools is no longer optional; it is essential for technological leadership in manufacturing and beyond.

Related Post

Xem Trực Tiếp Bóng Đá VTV6: Lịch Thi Đấu & Hướng Dẫn Chi Tiết Như Thực

Harvey Levin Partner: Shaping Legal Excellence Through Strategic Innovation and Client-Centric Vision

Dennis Oh Wife: The Private Life Behind the Public Spotlight

Ou Vs Texas Softball: Compare Streaming Wars with Spectacle of Ou vs Texas Live Streams and TV Coverage