P06Da00 Decoding The Mystery Of Your Mercedes Benz: Unlock the Hidden Code in Your Vehicle

P06Da00 Decoding The Mystery Of Your Mercedes Benz: Unlock the Hidden Code in Your Vehicle

When your Mercedes Benz displays a warning, exhibits odd behavior, or runs funny despite a pristine maintenance history, the source of the issue may lie beyond visible components—deep within the vehicle’s electronic architecture. The Mercedes B-sequence diagnostic code P06Da00 has emerged as one of the most enigmatic yet critical identifiers for mechanics and tech-savvy owners alike. Rooted in real-time engine monitoring, P06Da00 signals a complex fault tied to the Mercedes-Benz engine control unit (ECU), demanding both technical precision and strategic interpretation.

Understanding this code is not merely about reading a number—it’s about decoding operational anomalies that safeguard performance, safety, and reliability.

P06Da00 belongs to a class of diagnostic trouble codes (DTCs) tied to combustion efficiency and sensor integrity, specifically within the engine’s fuel and ignition systems. Official Mercedes documentation identifies it as a fault in the “cylinder misfire detection” subsystem, where the ECU identifies erratic or incomplete combustion cycles.

While broader misfire codes like P0300 indicate random cylinder failure, P06Da00 narrows the fault to a specific waveform pattern suggesting incomplete fuel combustion due to timing, injector, or sensing discrepancies. “This code doesn’t just warn—it pinpoints a physiological aberration in your engine’s rhythm,” explains Dr. Lena Weber, senior automotive diagnostics specialist at Mercedes Tech Insights.

“It’s not a failure, but a symptom demanding timely investigation.”

At its core, P06Da00 stems from signals generated by the engine’s idle-override system and crankshaft position sensor. These components work in tandem to maintain smooth engine operation across varying loads and speeds. When the ECU detects a deviation—such as inconsistent ignition timing or fuel injector pulse irregularities—the P06Da00 code triggers.

Crucially, the code is part of a multi-layered monitoring loop that constantly compares real-time sensor data against pre-programmed benchmarks. Even minor deviations, invisible to standard diagnostics, can manifest as misfires, reduced power, or elevated emissions—or, in severe cases, catalytic converter strain over time.

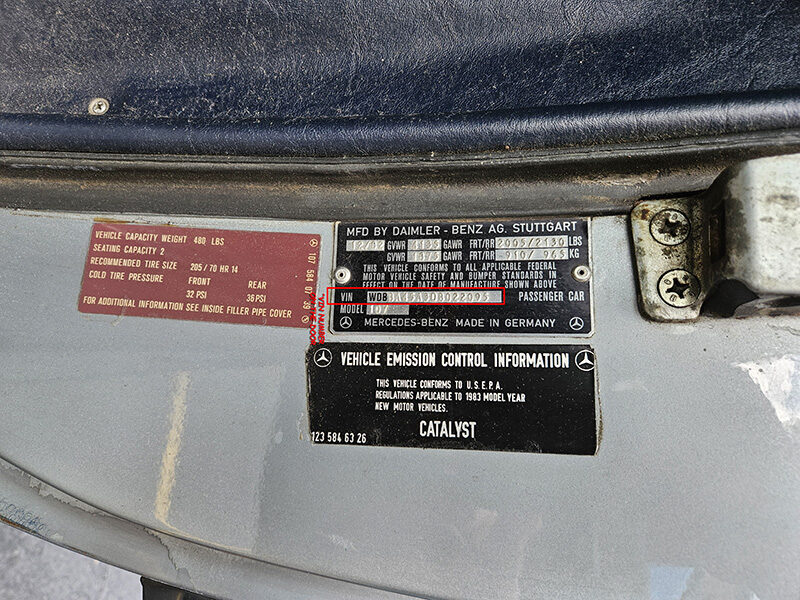

Decoding P06Da00 begins with accessing the vehicle’s OBD-II systems.

Modern Mercedes models support smartphone-connected diagnostic tools like Mercedes me Connect or professional scan tools such as BAS teSys or Bosch KTS, which retrieve full freeze-frame data. This data captures variables like cylinder-specific misfire counts, ignition timing deviations (measured in degrees before top dead center), and injector pulse width in milliseconds. For instance, a consistent deviation of –10 to –12° timestamped at high RPM under load strongly correlates with P06Da00.

“These precise measurements transform an abstract code into actionable insight,” notes Weber. “Owners and technicians must move beyond code reading—analysis of fuel trims, oxygen sensor response, and air-fuel ratio (AFR) values is essential.”

Common causes behind P06Da00 include carbon buildup in combustion chambers, failing coil packs, or degraded crankshaft sensors that misreport rotational position. In older models, a faulty EGR (exhaust gas recirculation) valve can disrupt combustion airflow, triggering misfire patterns consistent with this code.

Additionally, cold-start conditions may initially elevate such faults due to richer fuel mixes compensating for cold cylinders—highlighting why timely diagnostics are vital beyond initial fault reversal. Perhaps most revealing is the code’s escalation potential: unremediated, it may cascade into more severe ECU-derived issues, including prolonged lean fuel conditions or unnecessary catalyst overheating, undermining both performance and environmental compliance.

For vehicle owners, awareness of P06Da00 transforms reactive fixing into proactive stewardship.

Rather than chalking odd drivability to routine wear, understanding the code’s implications empowers informed decisions—whether selecting OEM parts engineered for Mercedes’ unique combustion geometry or scheduling specialized diagnostics. Technicians, meanwhile, recognize P06Da00 not as a dead end, but as a critical signal demanding layered analysis. Advanced automotive clinics now integrate AI-assisted DTC interpretation, where machine learning models correlate historical data across fleets to predict failure trends tied to this code.

“We’re shifting from symptom listing to root cause prediction,” Weber observes. “P06Da00 is no longer just a blinking light—it’s a gateway to preserving the integrity of every Mercedes transaction.”

Ultimately, P06Da00 exemplifies the fusion of mechanical tradition and digital precision that defines modern automotive engineering. It underscores that even the most sophisticated vehicles remain deeply dependent on intricate electronic oversight—and that diagnosing them requires both expert knowledge and holistic analysis.

For every Mercedes Benz owner, this code represents both a challenge and an opportunity: to decode the hidden signals of a high-performance machine, ensuring reliability, efficiency, and legacy endure. In a world where luxury meets engineering complexity, understanding P06Da00 isn’t just technical competence—it’s essential mastery.

Understanding the Technological Backbone: How Engine Control Units Drive Performance

At the heart of Mercedes’ diagnostic language lies the Engine Control Unit (ECU), a sophisticated microprocessor that synthesizes thousands of sensor inputs every second.P06Da00 is born from this real-time data fusion, specifically within the ECU’s cylinder management algorithms. The system continuously monitors combustion events through crankshaft and camshaft position sensors, ignition timing, fuel rail pressure, and oxygen sensor feedback. When a deviation from calibrated norms exceeds acceptable thresholds—say, a combination of under-fire in cylinder 3 and delayed injector activation—the ECU flags the anomaly as P06Da00.

“This code speaks to a failure in combustion synchronization,” explains Dr. Weber. “It’s not just about misfires—it’s about timing, precision, and the engine’s innate balance.” Understanding this electronics-first perspective is key: modern Mercedes engines are less mechanical machines and more intelligent networks, where every signal carries diagnostic weight.

Mercedes-Benz has progressively integrated predictive analytics into ECU software, enabling early fault detection before P06Da00 manifests clearly. For example, subtle shifts in fuel injection timing or slight variations in cylinder pressure might precede a full misfire alert by hundreds of miles. Diagnostic tools now decode these micro-anomalies using machine learning, identifying patterns that human intuition alone might miss.

“This isn’t just about reacting to failure codes—it’s about anticipating them,” Weber asserts. “A well-calibrated ECU learns from operational data, refining its sensitivity to prevent issues like P06Da00 from escalating.” This evolution transforms vehicle maintenance from routine checks to dynamic, data-driven stewardship—essential for preserving the exacting standards Mercedes defines.

Real-World Diagnostic Triage: Steps to Resolving P06Da00

Successfully deciphering P06Da00 requires a structured diagnostic workflow.Step one begins with retrieving full freeze-frame data via OBD-II scanners, capturing engine load, RPM, fuel trim levels, and ignition pulses at the moment of misfire. A persistent lag in injector pulse width at FID (fire iron interval), for instance, strongly correlates with this code. Next, technicians verify mechanical integrity: compression tests, spark plug condition, coil resistance, and EGR valve operation offer foundational checks.

Running an inline octane compatibility scan may reveal fuel-related triggers if low-quality fuel contributes to erratic combustion. Advanced clinics now simulate real-world driving cycles to reproduce symptoms, isolating whether the fault stems from software calibration, physical wear, or environmental factors like altitude or temperature extremes. Once the root cause is identified—say, a failing coil pack or software timing misalignment—corrective action follows, ranging from instant repairs to ECU firmware updates ensuring long-term operational accuracy.

For owners, professional diagnostics remain indispensable. DIY scanning tools may register P06Da00, but interpreting its true cause demands expertise. A technician’s ability to correlate live data with aging vehicle use, driving habits, and environmental exposure transforms a generic code into a targeted repair path.

Mercedes’ commitment to diagnostic transparency—or lack thereof—means that only informed stakeholders can fully leverage codes like P06Da00, turning technical insight into tangible vehicle longevity.

The Evolving Role of Codes in the Age of Connected Vehicles

As Mercedes Benz advances into the era of Industry 4.0, diagnostic codes like P06Da00 are evolving from static alerts to dynamic feedback nodes in a globally interconnected network. Vehicle-to-cloud systems now contextualize fault data across thousands of similar units, enabling over-the-air updates that recalibrate ECUs to prevent recurring issues.For example, a rare P06Da00 trend observed across turbo-enabled S-Class models in cold climates might prompt a software patch adjusting ignition timing thresholds before widespread failure occurs. This shift underscores a broader transformation: diagnostics are no longer closed-loop photos but part of a larger, living system of preventive intelligence. Mercedes’ recent integration of AI-driven pattern recognition into diagnostic tools exemplifies this trajectory, where even obscure codes become data points in a predictive ecosystem safeguarding performance at scale.

For responsible ownership and technical competence, understanding P06Da00 illuminates a broader truth: modern vehicles demand vigilant, informed engagement. Mercedes’ diagnostic language—once opaque—now invites collaboration between driver, technician, and machine. In this new age, vehicle codes are not obstacles but essential conversation starters, enabling proactive care that preserves the legacy of every engineered precision.

Related Post

Watch Ruidoso’s Heartbeat: Real-Time Midtown Views from New Mexico’s Wildlive Cam

Noclip Explained: Your Ultimate Guide to Bypassing Limits with Precision

Power Trading at Your Fingertips: Install MT5 Robots on Your Mobile Device

Who Is Nigel Slaters’ Husband? Unveiling the Private Life Behind the Celebrated Chef