Seriesonline Ac: The Precision Powerhouse Redefining Industrial Connectivity

Seriesonline Ac: The Precision Powerhouse Redefining Industrial Connectivity

In an era where seamless data exchange and system interoperability define operational excellence, Seriesonline Ac emerges as a transformative force in industrial automation. This advanced Device Access protocol, engineered for reliability and scalability, enables businesses to harness real-time communication across heterogeneous machines and software platforms. From smart manufacturing floors to distributed asset networks, Seriesonline Ac delivers the speed, precision, and security demanded by modern industrial ecosystems.

Its ability to unify legacy and next-gen equipment makes it an indispensable tool in the digital transformation journey.

The Technical Evolution: How Seriesonline Ac Drives Industrial Efficiency

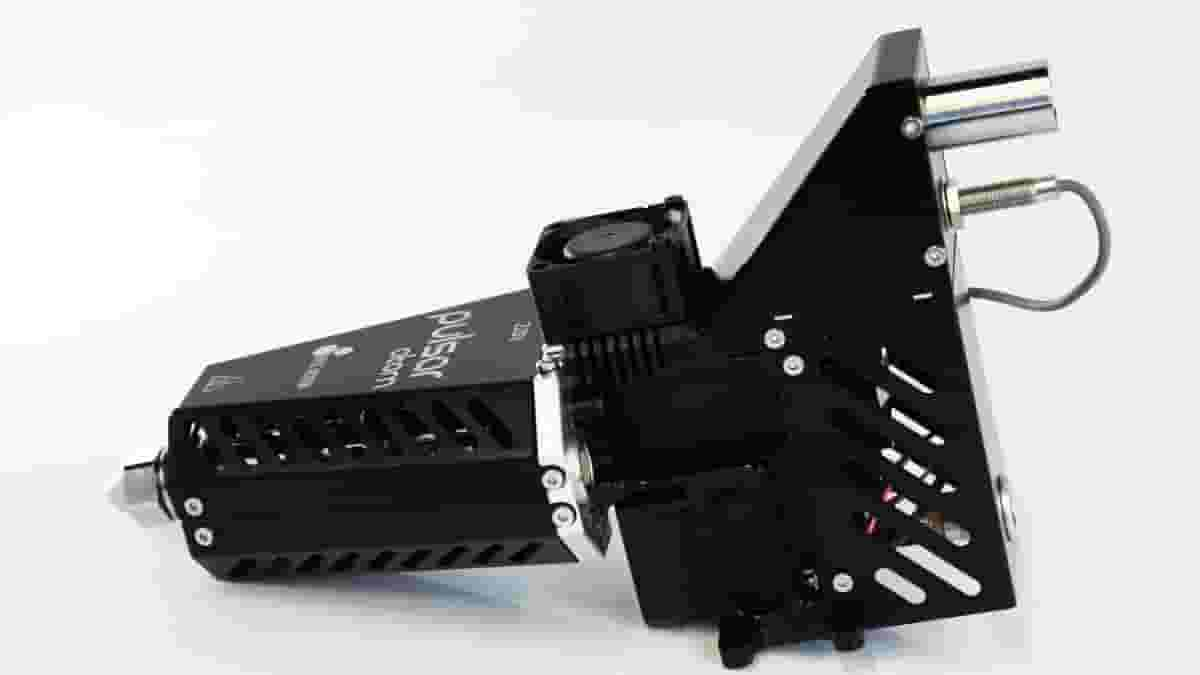

At its core, Seriesonline Ac is a refined evolution of serial communication systems, optimized for acoustic, wireless, and hybrid industrial environments. Unlike conventional serial protocols that struggle with noise interference and latency, Seriesonline Ac integrates adaptive signal processing and dynamic bandwidth management—features that ensure stable, high-fidelity data transmission even in electrically chaotic settings. “We designed Seriesonline Ac to eliminate bottlenecks,” explains Dr.

Elena Rostova, Chief Technical Officer at Seriesonline. “It doesn’t just transmit data—it interprets context, auto-corrects errors, and prioritizes mission-critical signals with millisecond responsiveness.”

Key technical strengths include:

- Noise-Robust Communication: Utilizes advanced error-correction algorithms that maintain integrity in high-electromagnetic interference zones, reducing packet loss by up to 98% compared to legacy systems.

- Low-Latency Protocol Stack: Optimized for real-time control loops, minimizing delay to sub-100ms—essential for automated production lines and remote monitoring dashboards.

- Hybrid Network Support: Native compatibility with both traditional RS-485 networks and modern wireless standards (LoRaWAN, Zigbee, NB-IoT), enabling frictionless integration across diverse infrastructures.

- Scalable Device Management: Centralized platform allows intuitive provisioning, firmware updates, and diagnostic tracking across hundreds of connected terminals.

These capabilities position Seriesonline Ac not merely as a communication layer but as a foundational pillar in industrial IoT architecture.

Real-World Performance: Case Studies in Industrial Transformation

Beyond theoretical promise, Seriesonline Ac delivers measurable ROI across sectors. In automotive manufacturing, one leading producer reported a 40% drop in unplanned downtime after deploying Seriesonline Ac to synchronize robotic arms and quality inspection systems.

The protocol’s precise timing coordination enabled synchronized machine operation previously unattainable with older systems.

In the energy sector, remote asset monitoring using Seriesonline Ac cut maintenance response times by 60%. Equipped with environmental sensors and secure, low-power transmitters, field teams receive instant alerts on equipment health, enabling proactive repairs before failures cascade.

“The platform’s reliability in harsh outdoor environments was pivotal,” notes Mark Chen, Field Systems Engineer at HydroGrid Solutions. “Unlike traditional RTUs, Seriesonline Ac maintains link stability during extreme temperature swings and voltage fluctuations.”

Another standout use case appears in agriculture: precision farming operations leverage Seriesonline Ac to connect soil moisture sensors, automated irrigation controllers, and weather stations across vast fields. The protocol’s efficient data handling ensures timely adjustments—boosting crop yield while minimizing water waste—proving vital in sustainable resource management.

Security and Future-Proofing: Building Trust in Critical Networks

As industrial systems grow increasingly connected, cybersecurity becomes non-negotiable.

Seriesonline Ac addresses this with end-to-end encryption, multi-factor authentication, and regular firmware hardening to defend against cyber threats. “Our architecture is built on defense-in-depth principles,” states Rostova. “Every data packet is authenticated, encrypted, and monitored—guardrails that evolve with emerging risks.”

Looking ahead, Seriesonline Ac is engineered to integrate emerging technologies like edge computing and AI-driven analytics.

Its open API framework supports third-party developers, fostering innovation ecosystems where custom applications enhance operational intelligence. The protocol also aligns with global standards (IEC 62591, ISA100.110), ensuring compatibility with evolving regulatory landscapes and industry best practices.

For organizations investing in smart factories, smart grids, and distributed monitoring, Seriesonline Ac represents more than a protocol upgrade—it delivers a strategic advantage.

By turning fragmented data silos into a unified, actionable intelligence network, it empowers industries to operate smarter, faster, and more securely in an interconnected world.

Seriesonline Ac does not just transmit data—it transforms how industries connect, analyze, and respond. In a landscape where reliability and speed define competitiveness, it stands as a benchmark for next-generation industrial communication, bridging legacy and innovation with precision and purpose.

Related Post

Find Your Closest Uniqlo on the Las Vegas Strip in Seconds

Spitting Stitches After a Month: What Happens When No One Notices

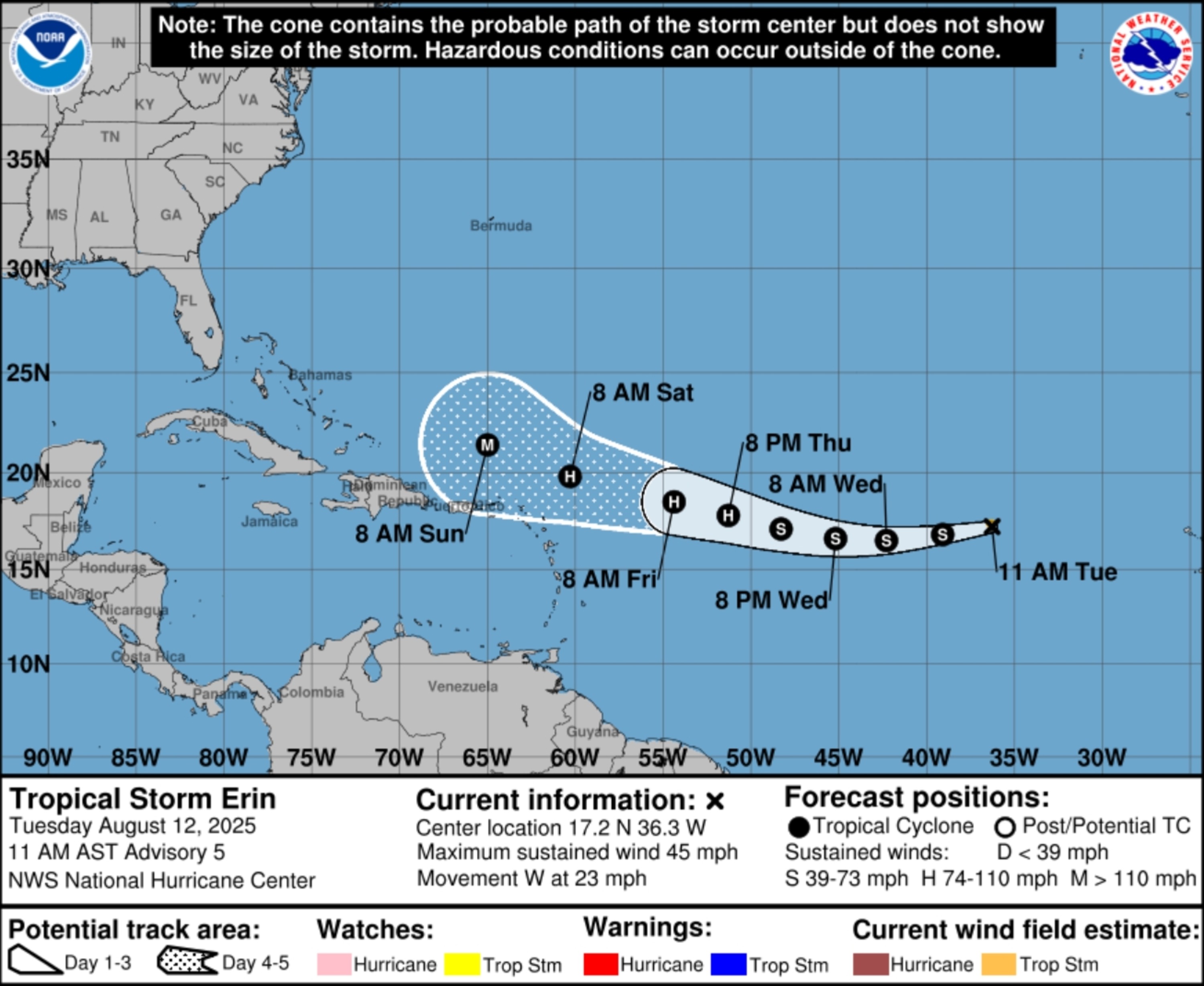

Hurricane Erin’s Path Deciphered: How Spaghetti Models Revolutionize Storm Prediction

Pressure Big Money Blitz: Unlocking Fast Failure in High-Stakes Fintech Ventures