Siemens S7-1200 PLC: The Powerhouse Redefining Industrial Automation

Siemens S7-1200 PLC: The Powerhouse Redefining Industrial Automation

Operating at the heart of modern manufacturing lies the Siemens S7-1200 Programmable Logic Controller, a workhorse of industrial automation renowned for its robust performance, scalability, and future-ready flexibility. Engineered for demanding environments, this compact yet powerful PLC has become a benchmark in smart factory deployment, offering operators and engineers a reliable platform that merges legacy compatibility with cutting-edge digital innovation. From discrete control to advanced motion applications, the S7-1200 delivers efficiency, precision, and resilience — making it an indispensable tool in today’s connected industrial landscape.

Core Specifications: Where Performance Meets Compact Power

The Siemens S7-1200 stands out not only for its functionality but also for its carefully engineered specification deck, designed to fit seamlessly into diverse production systems. At its core, the PLC integrates a 1.5 GHz processor with a sophisticated TIA Portal-compatible architecture, enabling high-speed data processing and real-time control across complex automation workflows. With support for up to 1,048 I/O points — including digital, analog, timers, counters, and communications modules — it delivers exhaustive interfacing versatility.Key technical parameters include: - CPU: Siemens 1.5 GHz embedded processor with integrated memory and storage - Memory: Up to 256 MB RAM (expandable via SIMM or DDR) and 256 MB ROM - I/O: Expandable via a modular input/output board system supporting 1,048 channels (digital, analog, special functions) - Communication: Built-in support for PROFINET, PROFIBUS DP, EtherCAT, EtherNet/IP, and Modbus TCP - Power: Rated for industrial power supply (24V–65V DC), with wide temperature tolerance (-40°C to +85°C) - Enclosure: IP68-rated, mounting-friendly design ideal for harsh industrial environments “Designed with faceplate mounting and modular expansion in mind, the S7-1200 brings compact size without sacrificing capability,” notes Dr. Markus Weber, Control Systems Engineer at Siemens. “It’s built to last in the most demanding plants — where uptime and precision are non-negotiable.”

Advanced Features That Drive Smart Manufacturing

Beyond basic control, the S7-1200 integrates a suite of intelligent features that position it at the vanguard of Industry 4.0.Engineers leverage its rich diagnostic and self-monitoring capabilities to minimize unplanned downtime and enhance system transparency.

- TwinCAT 3 Integration: The PLC is fully aligned with Siemens’ TwinCAT 3 real-time control platform, enabling seamless transition from PLC programming to PC-based HMI/SCADA visualization and advanced simulation.

- Edge Computing & Data Aggregation: Built-in security features and gateway-ready I/O allow localized data processing, reducing cloud latency and supporting real-time analytics on the factory floor.

- Profile 968 Compatibility: Supports modern industrialConnect standards, enabling interoperable integration with robotics, motion systems, and smart sensors.

- In-depth Diagnostics: Proactive fault detection, predictive maintenance alerts, and comprehensive log analysis reduce troubleshooting time and extend equipment life.

- Modular Safety Options: Included SafeSoft technology supports compliant integration of safety-rated I/O, adding intrinsically safe control to emergency stops, light curtains, and collaborative robot interfaces.

Transformative Benefits for Modern Industry

Adopting the Siemens S7-1200 delivers tangible advantages that directly impact operational excellence.Its plug-and-play integration, fueled by extensive vendor ecosystem support, slashes commissioning time and lowers total cost of ownership. With durability underscored by extended operational ranges and deliberate thermal management, equipment longevity improves, reducing long-term maintenance burdens. Key benefits include: - **Scalability**: Expand I/O and functionality via add-on modules without overhauling existing infrastructure.

- **Reliability**: Optimized hardware ensures consistent performance in continuous operation, critical for 24/7 industrial environments.

- **Future-Proofing**: Open architecture and compatibility with digital twin and IoT platforms prepare plants for next-gen automation.

- **Productivity Gains**: Real-time diagnostics and energy-efficient operation reduce waste, improve line efficiency, and boost output.

- **Simplified Troubleshooting**: Intuitive user interface and centralized diagnostics reduce mean time to repair (MTTR) by up to 40%, according to field data.

This combination of forward-thinking design and proven reliability positions the S7-1200 not just as a tool, but as a strategic investment for manufacturers aiming to thrive in an automated future.

Real-World Impact: Case Studies Mark the Difference

Manufacturers spanning automotive, food processing, and heavy machinery have witnessed transformative results after deploying the S7-1200. In a recent European automotive shift line, integration reduced downtime by 42% and enabled dynamic reconfiguration of production cycles in under two hours — a game-changer for mixed-model assembly.Meanwhile, a North American food processor leveraged the PLC’s edge analytics to cut energy consumption by 18% while enhancing batch consistency. These examples reflect a broader trend: the S7-1200 empowers not just automation, but adaptability and intelligence. With Siemens continuing to innovate within the S7 ecosystem — introducing enhanced AI-ready processing and deeper cloud connectivity — the S7-1200 remains more than a PLC: it’s the cornerstone of scalable, resilient, and smart industrial operation.

Why the Siemens S7-1200 Stands Out in a Crowded Market

In an era of rapid technological evolution, the Siemens S7-1200 distinguishes itself through a rare balance of reliability, openness, and openness to innovation. Unlike legacy systems constrained by proprietary silos, its transparent architecture supports cross-platform integration, real-time decision-making, and secure expansion. Combined with Siemens’ global support network, extensive training resources, and a vast ecosystem of partner solutions, the S7-1200 offers more than hardware — it provides a pathway to digital leadership.As industrial demands grow more complex, the S7-1200 delivers a proven, extensible foundation for automation leaders. It bridges the gap between traditional control and next-generation smart manufacturing, ensuring that factories not only keep pace with change but anticipate and lead it. In the end, selecting the Siemens S7-1200 is about more than choosing a PLC — it’s about embracing a future where precision, efficiency, and resilience are engineered into every control cycle.

Related Post

What Is NetSuite CRM? How Its Core Features Power Enterprise Growth

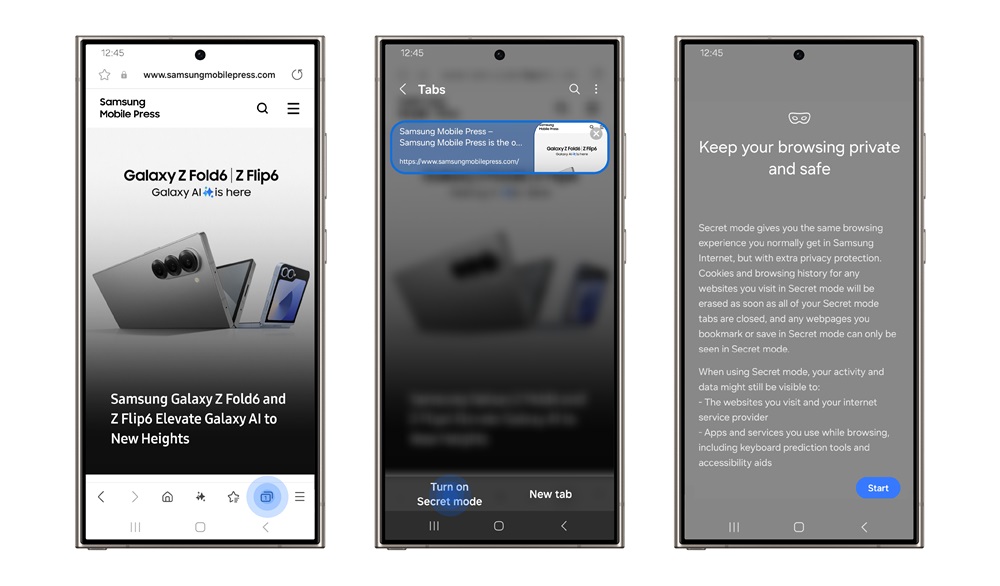

What Is Samsung Browser? Unlocking Speed, Security, and Smart Experience on Your Device

How Yahoo.com Powers America’s Daily Digital Experience with Speed, Relevance, and Consumer Trust

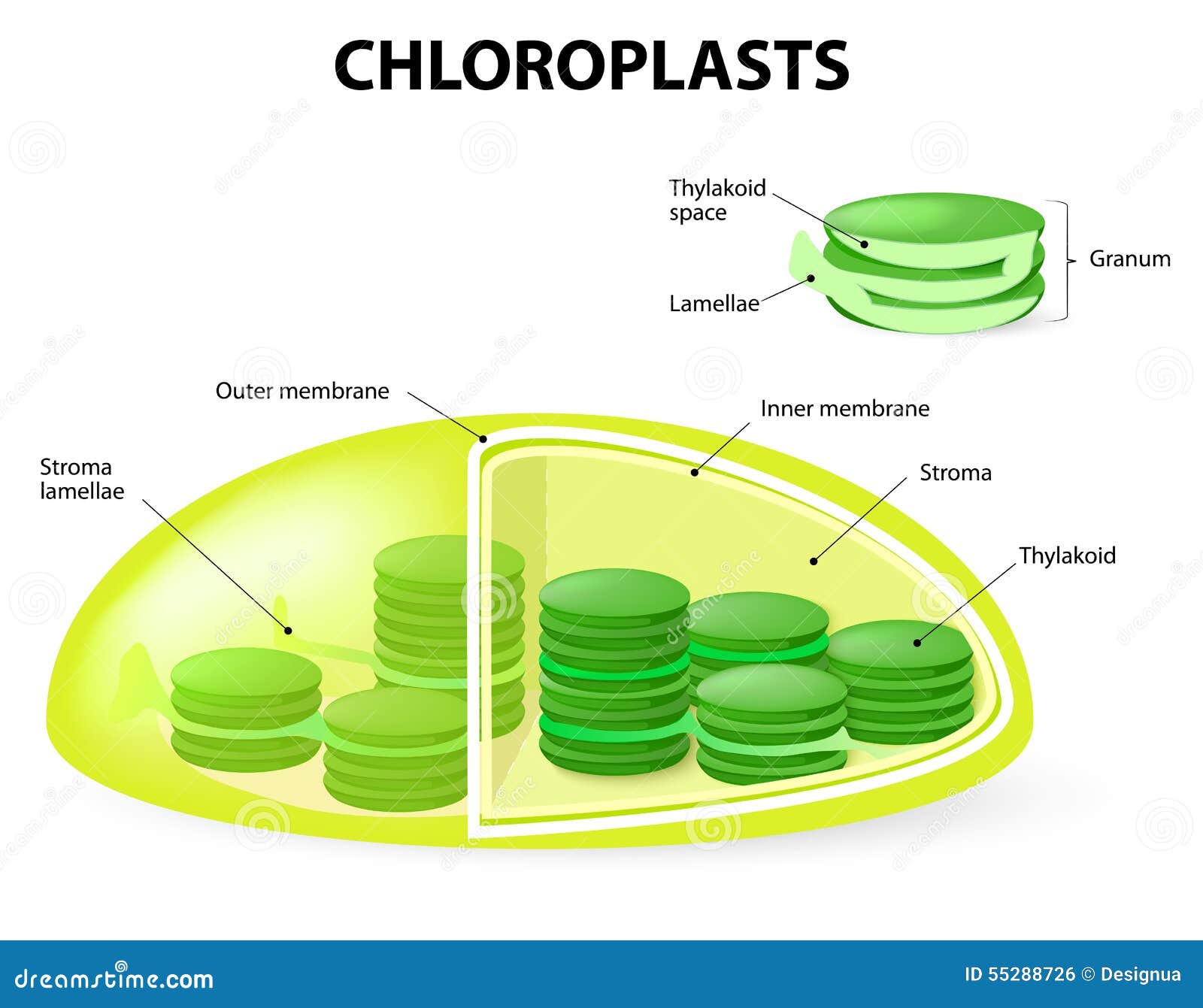

The Hidden Powerhouses of Photosynthesis: Where Chloroplasts Reside Inside Plant Cells