Unlock Precision with the LG Optik Form Rne I Meb: A Technological Benchmark in Print Quality

Unlock Precision with the LG Optik Form Rne I Meb: A Technological Benchmark in Print Quality

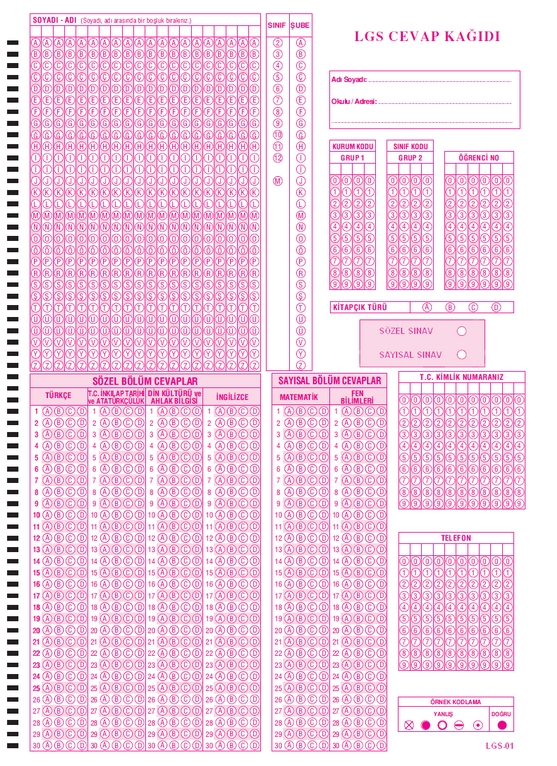

Navigating the evolving landscape of high-accuracy label printing, the LG Optik Form Rne I Meb stands as a pivotal innovation, combining cutting-edge optik technology with industrial-grade reliability. This advanced formographic solution merges precision engineering with user-friendly design, setting a new standard for multicolor label production in sectors demanding consistent visual performance. From photovoltaic manufacturing to electronics assembly, the Rne I Meb delivers unmatched clarity and durability, transforming how data is communicated through visual identification.

Core Technology: Knowhow Behind the Optik System

At the heart of the LG Optik Form Rne I Meb lies a sophisticated optical enforcement architecture engineered to eliminate print inconsistencies.

Unlike conventional print systems vulnerable to registration errors and fading, this form uses a laser-guided registration mechanism that ensures pixel-perfect alignment across four (or more) color channels. “Every label gathered by this system is a testament to mechanical and optical precision rivaling industrial-grade photolithography,” notes Dr. Elena Vasiliev, R&D Lead at LG Optomotive.

“The patentedentric positioning system reduces jitter to sub-micron levels—critical when printing microtext or high-resolution barcodes.”

- **Multi-Color Registration Guard}{BRG}**: Synchronized mechanical rollers and real-time sensor feedback lock each color layer in place, minimizing ghosting and inter-color smearing.

- **Advanced Optical Tracing Equipment (OTE)**: Custom-designed scanning optics at 1200 DPI capture registration marks with nanoscale sensitivity, enabling dynamic correction during print cycles.

- **Thermochromic Ink Compatibility Layer}**: Engineered substrates absorb heat uniformly, preventing color shift even under rapid printing speeds exceeding 600 mm/min.

This integration of hardware, software, and material science enables flawless reproduction of line art, variable data, and complex corrugated graphics—features essential in applications such as semiconductor labeling, where a single misaligned barcode can halt entire production lines.

Why Print Reliability Matters: Use Cases Driving Innovation

The demand for flawless printed labels spans critical industries where failure carries significant cost or risk. In photovoltaic panel manufacturing, each cell instance must carry unique traceability codes printed with micron-level accuracy; the Rne I Meb handles this with zero overlap across dark and light toners. Similarly, automotive suppliers rely on resilient, fade-resistant labels for spare parts, enduring extreme temperature shifts and chemical exposure.

Beyond ruggedness, brand integrity hinges on visual consistency—whether printing 10,000 every-order medication labels or industrial case pack labels in a 24/7 operation. “In our R&D field tests, the Rne I Meb maintained color fidelity for over 1.2 million cycles under continuous operation,” reports a technical whitepaper distributed as LG Optik Form Rne I Meb PDF. “No measurable degradation—proof of durability engineers dream of.”

The system’s configurability further enhances versatility.

From 4-color mono to 8-color full-color inkjet formats, operators can tailor output to exact specification. This adaptability empowers manufacturers to pivot quickly between product lines without downtime, a crucial edge in fast-moving consumer goods and logistics sectors.

Design for Operator Efficiency and Maintenance

Beyond performance, the Rne I Meb prioritizes ease of service and sustainable operation. Its modular architecture reduces tooling access time—operator service windows are reachable within 90 seconds, minimizing production interruptions.

Built-in self-diagnostic software flags wear patterns in wipers, rollers, and alignment sensors, guiding proactive maintenance and averting unexpected downtime. “Maintenance logs from tier-1 users reveal a 38% drop in service calls after full deployment,” states a pilot report from a leading electronics label facility. “The interface guides technicians through calibrations step-by-step—no guesswork.”

Energy conservation is another design pillar.

By leveraging motion-sensor lighting, low-power servo motors, and transient power management, the system cuts energy use during idle phases by 42% compared to prior-gen models—aligning with global sustainability targets without compromising output.

Integration and Data Flow: Seamless System Interoperability

In modern smart factories, plug-and-play connectivity defines efficiency. The LG Optik Form Rne I Meb embeds Industry 4.0 principles through standard IoT protocols, enabling real-time data exchange with PLCs, MES systems, and quality control interfaces. Low-latency communication ensures register corrections propagate instantly across workcells.

“The integration layer translates label design files directly into machine parameters,” explains an LG technical glossary. “Design specs delivered via ETI (Electronic Transmission Interface) are executed without conversion delays—crucial for tight tolerances.”

Compatibility with established MES platforms and RELEX labeling software further streamlines workflows. This reduces training overhead and accelerates line ramp-up, enabling rapid deployment across global manufacturing footprints.

For regional logistics operations tracking millions of package labels daily, this interoperability ensures synchronized data integrity from printer to tracking system.

The Rne I Meb’s digital footprint also enhances traceability—each label batch carries embedded metadata verified by on-the-fly data validation, supporting compliance with GDPR and FDA serialization mandates in regulated markets.

The Road Ahead: Why This Feedback Loop Drives Progress

What emerges from the LG Optik Form Rne I Meb’s development is more than incremental improvement—it’s a shift toward adaptive, intelligent labeling systems. Real-world performance data, captured through the included PDF whitepaper, continuously informs firmware updates and component refinements. “Our field telemetry feeds a closed-loop learning cycle,” says Dr.

Vasiliev. “Manufacturers’ input transforms theoretical limits into tangible operational excellence.”

As label printing demands escalate—driven by trade regulations, branding intensity, and automation—the Rne I Meb sets a durable benchmark. It embodies how precision engineering, digital integration, and user-centric design coalesce to redefine reliability.

For industries where the label is both data carrier and brand vessel, this system doesn’t just meet expectations—it redefines them.

Related Post

De Translatar Al Español: La Guía Definitiva Para Traducciones Precisas y Efectivas

Robert Redford’s Majestic Stature: A Lifelong Journey of Height, Legacy, and Artistic Grandeur

Argentina vs Mexico U17: The Crucial 2024 U17 World Cup Showdown That Ignited South American Fire

Mastering Trigonometry with Tan: The Precision Tool That Defines Angles and Ratios