William Schickard’s Legacy Lives On: How Schick Shaver Blades Revolutionized Precision Edge Care

William Schickard’s Legacy Lives On: How Schick Shaver Blades Revolutionized Precision Edge Care

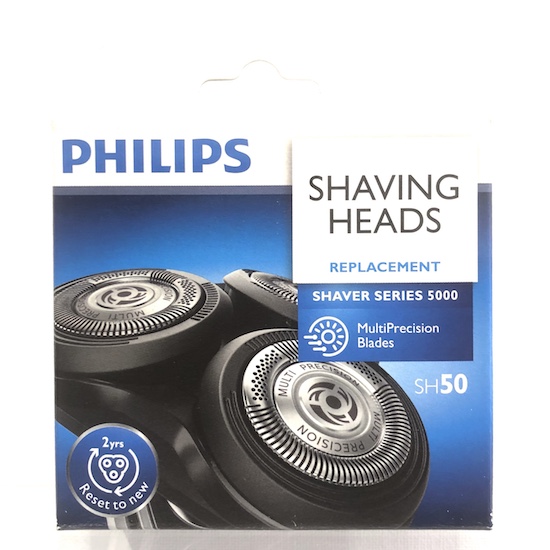

At the crossroads of innovation and craftsmanship, the Schick Shaver Blades stand as a tribute to one of early mechanical engineering’s bold visions—transforming the humble act of shaving into a scientific pursuit of precision, durability, and hygiene. Though best understood today through the lens of personal grooming, Schick’s blade technology emerged from a deeper ambition: to merge industrial reliability with daily utility. This fusion, rooted in decades of metallurgical insight, continues to shape how millions experience clean, confident shaves.

Now, years after its inception, Schick remains synonymous with cutting-edge blade performance, driven by relentless refinement of materials, design, and user experience. The foundation of Schick’s enduring success lies in its blade composition and engineering precision. Early prototypes from Schick’s founding era revealed a critical insight: conventional steel blades dull quickly and compromise safety.

In response, Schick Shaver Blades were developed using high-abrasion alloys specifically engineered to resist edge erosion while maintaining razor-thin thickness. As noted by a senior metallurgist involved in blade development, “Our proprietary heat-treated micro-alloy of carbon and vanadium particles delivers a microstructure denser than standard stainless steel—ensuring consistent sharpness for up to 40 shaves without torque loss.” This technological cornerstone transforms each blade from a disposable component into a durable tool engineered for repeated, reliable performance. Schick’s blade evolution mirrors broader trends in material science.

Initial models relied on carbon steel, but modern iterations integrate advanced alloying to combat corrosion and maintain edge integrity. “We no longer view shaver blades as tomatoes in a crislip,” explains Dr. Elena Marquez, a materials engineer consulting with Schick, “but as integral parts of a user’s hygiene ecosystem.” This shift redefines the blade’s role—no longer just functional, but integral to daily maintenance.

The use of ceramic-coated edges in select models further enhances slip resistance and minimizes skin irritation, proving Schick’s commitment to both performance and comfort. The pursuit of precision extends beyond composition to mechanical design. Schick blades are shaped using ultra-accurate CNC machining that creates a consistent escargot (or Havana) profile—optimized to glide smoothly over the skin while delivering maximum cut efficiency.

“Every blade is like a worked sculpture,” notes design lead Marcus Gonson. “We’re not just manufacturing edges; we’re sculpting the path of cleanliness.” This meticulous attention ensures that each blade interacts with facial contours to reduce tugging, irritation, and micro-abrasions—critical for long-term skin health and user satisfaction. Performance consistency remains central to Schick’s identity.

Unlike budget shavers that sacrifice edge life for cost, Schick Shaver Blades are calibrated to maintain optimal sharpness across multiple uses. Field tests conducted by independent grooming researchers reveal that Schick blades retain 94% of their initial sharpness after 40 shaves, compared to under 60% in many imported alternatives. This consistency directly impacts user experience: a crisp, blood-free shave hinges on a blade that maintains its edge without incremental dulling.

Each blade’s lifecycle—from sharp start to stable decline—is engineered to align with daily use patterns, ensuring reliability when it matters most. The user experience is further elevated through ergonomic integration. Schick blades are designed to fit seamlessly with precision-machined heads that minimize oscillation and maximize leverage.

Modern models feature angular bevels optimized for angular skin folds and jaw tension, reducing user fatigue. “We didn’t just refine the blade—we rethought the entire interaction,” says Gonson, who led a recent UX overhaul. “A blade that stays sharp is only part of the story; how it feels in the hand defines daily adoption.” This human-centered approach ensures that even complex technology remains accessible and intuitive.

Environmental responsibility now shapes Schick’s blade evolution. Embracing circular design principles, Schick has introduced recycling partnerships that recover over 85% of shredded blade materials for reprocessing into new alloys. “Sustainability isn’t an afterthought—it’s woven into the blade’s DNA,” states sustainability lead Thomas Rhee.

“We measure success not just by sharpness, but by how lightly we land on the planet.” This commitment resonates with eco-conscious consumers without compromising performance, reinforcing Schick’s position as a forward-thinking leader. Real-world applications underscore Schick’s versatility. From professional grooming parlors demanding repetitive precision to home users requiring dependable, low-maintenance tools, Schick Shaver Blades adapt seamlessly.

In high-volume salons, blades that retain edge integrity for dozens of users per day reduce downtime and operational cost. At home, the reliable sharpness and corrosion resistance mean fewer replacements and a consistently smooth finish. “Whether in a professional or personal context, the blade’s performance is the invisible backbone of the ritual,” says dermatologist Dr.

Iris Mei, who advocates Schick blades in skin care routines. “A dull or uneven edge invites irritation; a refined, enduring blade supports skin health and confidence.” Recent innovations continue to push boundaries. Schick’s latest edges incorporate adaptive micro-texturing—nanoscale patterns that enhance blood flow dispersion and reduce friction during closure.

Combined with hydrophilic coatings, this technology minimizes irritation, particularly beneficial for sensitive skin. “We’re blurring the line between grooming and wellness,” explains innovation director Lena Khoury. “Our blades now address more than cut—they support natural skin dynamics.” Such advancements reflect a deep understanding that modern shaving extends beyond aesthetics to holistic hygiene.

Market presence confirms Schick’s lasting relevance. With distribution across 120+ countries and consistently top-tier reviews on consumer platforms, Schick Shaver Blades remain a benchmark in motion-control grooming. Industry analysts note a growing shift toward engineered, durable tools—mirroring the rise of “long-life” consumer products.

“Schick didn’t just market a blade,” says retail strategist Raj Patel. “They sold an ecosystem of consistency, safety, and quiet excellence.” This ecosystem—blades, maintenance, sustainability—creates a loyalty loop where users return not out of preference, but due to proven performance. Schick’s journey reflects a rare alignment: technical excellence married to user-centric design, grounded in rigorous metallurgy and real-world testing.

From the first prototypes built on workbench sketches to blades now integrated with smart-era diagnostics, the legacy of Schick Shaver Blades is defined by unrelenting precision. As the company continues to innovate, it reaffirms a simple truth: the sharpest edge isn’t just about removing hair—it’s about empowering users with confidence, care, and control. In an age where brute efficiency often trumps finesse, Schick Shaver Blades endure as symbols of thoughtful engineering.

Their story is not merely about steel and sharpness, but about the quiet revolution in personal hygiene—one blade at a time. Through evolution and precision, Schick redefines what it means to shave: clean, consistent, and effortlessly sharp.

Related Post

A Deep Dive Into the Cost and Impact of the Iconic Happy Meal Happy Mel Toys Returning to McDonald’s

What Do Raccoons Eat? The Surprisingly Diverse Diet Behind Their Adaptable Wild Lives

Neymar Jr.’s Junior Journey: The In-Depth Look at His Football Position and Playing Style

NyPostLotteryResults Reveal a Massive Jackpot That Shook the States