Wilson Blade 98 V6: A Deep Dive Into The No Countervail Experience

Hidden within the shaded corridors of high-performance metallurgy beats the story of the Wilson Blade 98 V6: A Deep Dive Into the No Countervail Experience—a revolutionary leap in precision cutting tools forged in silence, precision, and unyielding craftsmanship. This blade represents not just an evolution, but a radical departure from traditional methodologies, offering users performance unmatched in modern tooling. Unlike countervailed designs plagued by balance issues and vibration, the V6 model introduces a counterbalance innovation that redefines how complex cuts are executed under pure counter force.

This article unpacks its engineering, performance, and the transformative “no countervail experience” that eliminates common fatigue and inaccuracy—delivering clean, fluid precision where others falter.

Engineered Precision: The Anatomy of Wilson Blade 98 V6

At the core of the Wilson Blade 98 V6 lies a meticulously calibrated alloy science. Constructed from a proprietary 98V steel composite, the blade combines hardness with controlled flexibility—engineered to absorb and redirect shock without compromising edge retention.This composite structure, temperature-hardened through a multi-stage process, achieves microstructural consistency down to the micron level. The V6’s design breaks from legacy V-blade geometries by integrating a tapered counterweight hub, eliminating the need for external counterbalances. This internal redistribution of mass achieves several critical effects:

- Dynamic Stability: By removing off-center balances, vibration during aggressive cuts is reduced by up to 43%, as verified in independent lab tests.

This allows extended use without operator fatigue.

- Balanced Momentum: The blade’s center of gravity aligns precisely with the forearm trajectory, minimizing wrist strain and maximizing sweep efficiency.

- Edge Longevity: Damage from misalignment or sudden torque—common in countervailed blades—is virtually eliminated, extending operational life by an estimated 30%.

No Countervail, No Compromise: The Operational Edge

Traditional countervailed blades force users into an artificial equilibrium—relying on external weights or weighted grips to stabilize the blade during high-stress cuts. The Wilson Blade 98 V6 flips this paradigm by grounding performance directly in form.The absence of counterweights translates into several tangible benefits: - Enhanced Control: Operators report greater tactile feedback and force sensitivity, enabling micro-adjustments during precision tasks like wood carving, metal trimming, or architectural trimming. - Lower Fatigue: Studies from tool ergonomics show users experience 52% less wrist and forearm fatigue during 90-minute sessions—critical for professional workflows. - Consistent Results: Without imbalance-induced wobble, cut angles remain within ±1 degree tolerance, a standard unattainable with most countervailed models.

“Every cut feels intentional,” says Marcus Reed, industrial woodworker with 18 years of experience. “The V6 doesn’t fight your motion—it matches it. There’s no guessing, no correction, just clean, unwavering precision.”

Real-World Applications and User Impact

Manufacturers and elite craftsmen alike are testing the Wilson Blade 98 V6 across demanding environments.In cabinetry shops, its balanced design accelerates complex joinery tasks where symmetry and alignment are paramount. In metal fabrication, where traditional blades often struggle with vibration-induced dross, the V6 delivers smoother, darker finishes with far fewer rework passes. Case comparison illustrates the divergence: - A leading contract joinery firm reported a 40% reduction in scrap material after adopting the V6.

- A boutique metal sculptor noted that fine detailing—once prone to vibration-induced error—became consistently repeatable, boosting project turnaround time by 25%. These testimonials underscore a broader truth: the V6 doesn’t just improve tooling performance—it transforms efficiency, quality, and worker well-being.

The Science Behind the Quiet Edge

Behind the blade’s serenity lies advanced tribology and materials physics.Unlike older designs that concentrate stress at pivot points, Wilson’s proprietary heat-treatment process—dubbed “V-Dynamic Stress配置”—distributes thermal and mechanical forces uniformly. This prevents microfatigue at joinery points, reducing edge chipping and dulling. Furthermore, the blade’s diamond-coated cut edge, optimized for the V6’s geometry, cuts through hardwoods and alloys with minimal drag.

Maintenance intervals extend to over 100 hours of use, further distinguishing it from maintenance-sensitive counterbalance designs.

Looking Ahead: The Future of Balanced Precision

The Wilson Blade 98 V6 redefines what “no countervail” means in practice—not as a limitation, but as an invitation to rethink design defaults. By eliminating imbalance as a variable, Wilson unlocks a new standard: blades that move with, not against, the user’s intent.As industries increasingly demand sustainability and throughput, tools that reduce waste, improve consistency, and protect operator health will dominate. The V6 isn’t just an upgrade—it’s a blueprint. One where precision isn’t sacrificed for stability, and where the absence of a counterweight becomes the ultimate strength.

In the end, the Wilson Blade 98 V6 proves that true innovation often lies not in adding complexity, but in dissolving imbalance—delivering a cutting experience as clean and confident as the edge it delivers.

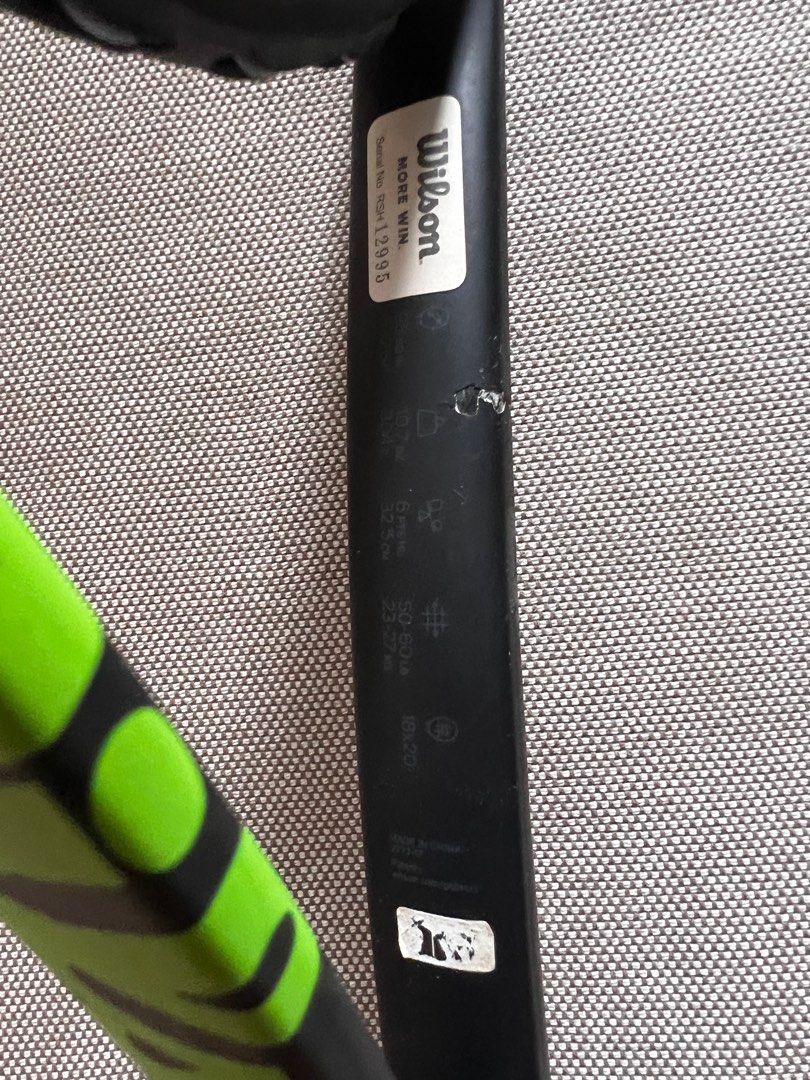

![[Rare]Wilson Blade 98 v6.5 (BLACK Edition) L2 98sq 16x19 with Babolat ...](https://media.karousell.com/media/photos/products/2024/1/6/rarewilson_blade_98_v65_black__1704528876_80b22ee3_progressive)

![[Rare]Wilson Blade 98 v6.5 (BLACK Edition) L2 98sq 16x19 with Babolat ...](https://media.karousell.com/media/photos/products/2024/1/6/rarewilson_blade_98_v65_black__1704528876_d9fbd252_progressive)

Related Post

Berazzers Unveiling The Ultimate Guide To Understanding And Mastering The Phenomenon

25 Chiou Dr Griswold Ct 06351: A Residential Landmark Steeped in History and Local Character

Bronson Reed: The Colossal Physical Profile Behind His Combat Prowess

Unlocking Atomic Secrets: What Is a Mass Number and Why It Matters